As technology continues to evolve, automation demand is upsurging. Automation saves labor, energy and time, but downtime can be disruptive and expensive. High-speed production, continuous movement and rugged environments are integral parts of automation, making connection reliability, especially challenging. To address this issue, VSI with its decades of experience designing, manufacturing and testing cables for automation infrastructures - offers an extensive range of industrial automation cables that cover both automation and process control and ensure operational reliability. Expert in-house engineers design and manufacture a wide range of custom cable assemblies and wire harnesses that include high power, overmolded and sealed connector options that support all industries.

Some major types of cable assemblies designed and manufactured.

-

Overmolded Cable Assemblies

Molex designs and manufactures custom overmolded cable assemblies in multiple circuit sizes and cable lengths, providing rugged strain relief at the interface between the connector and the jacketed cable.

Consumer, industrial and industrial automation applications often need cables that can endure bending and repeated plugging/unplugging. Molex Custom Overmolded Cable Assemblies provide strain relief which reduces mechanical stress on wires and terminals.

Often when consumer, home appliance and telecommunication customers need cable assemblies, they need multiple vendors to acquire connectors, cables and the actual assembly. Molex is a global manufacturer of connectors and cable assemblies, providing a complete connectivity solution.

-

Sealed Cable Assemblies

Sealed Cable Assemblies, with an IP67- or IP69-rated connector at one end and a standard wire-to-board connector at the other, deliver reliable connectivity for harsh-environment applications.

In outdoor and electric vehicle products, customers often request IP-rated connector and cable assemblies to ensure performance in wet, dusty environments. Molex Sealed Cable Assemblies can provide IP65, IP67 or IP69 rated functions.

Currently, consumer, commercial vehicle and industrial automation OEM assemblers do not have the technology and capability to design a sealed cable assembly. Molex provides a total connector and cable assemblies solution, and we have a design team that work closely with customers.

-

High-Power Cable Assemblies

High-power cable assemblies offer discrete and overmolded cables, ranging from 6 to 12 AWG, and deliver medium- to high-voltage options, ranging from 300 to 600V.

Designing Power and Signal high-power cable assemblies for consumer products and automobiles involves engineering and tooling costs, hindering the profit margins of end products. Molex has the expertise and infrastructure to crimp, poke, wire strip, splice, pot, ground, compound, test, and more, with different materials that include PVC, silicon, epoxy, XLPE and TSLF (HD) to avoid high tooling costs.

-

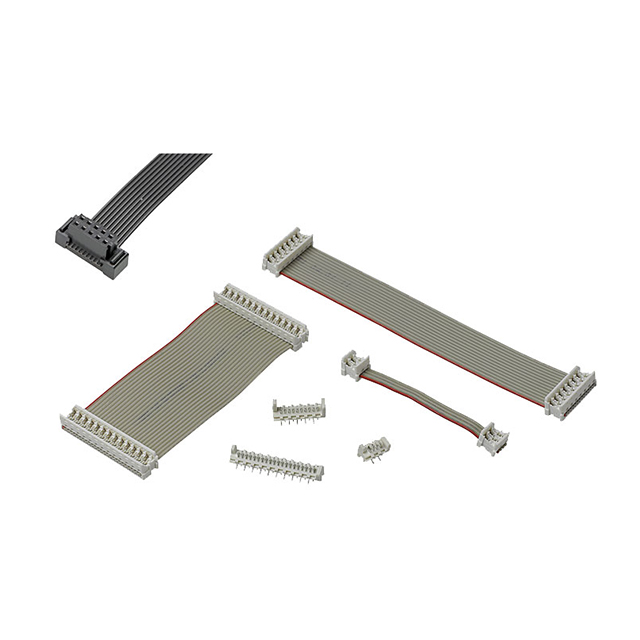

Ribbon Cable Assemblies

Molex Ribbon Cable Assemblies offer a range of options using different insulation displacement termination (IDT) connector families from Molex, such as Picoflex and Milli-Grid.

Molex is a one-stop-shop for cable assemblies; customers can obtain both the connector and the entire ribbon cable assembly built from one vendor, Molex. They can also benefit from the insightful contribution of Molex engineering.

Molex can provide complete custom solutions for ribbon cable assemblies supporting OEM customers with their design requirements.

-

Heavy Duty Connector Assemblies

Rugged cable assemblies for Indusrial equipments, testing, railways rolling stock and other robust applications.

-

Sealed Automotive ECU and BMU Assemblies

Entire automobile connectivity with signals originating from ECU and BMU.